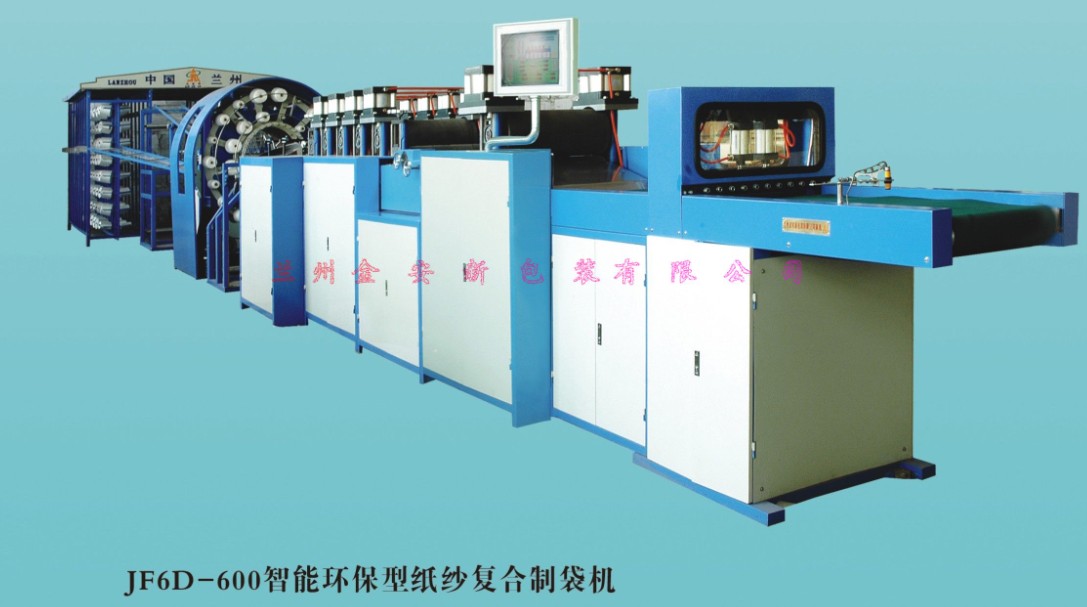

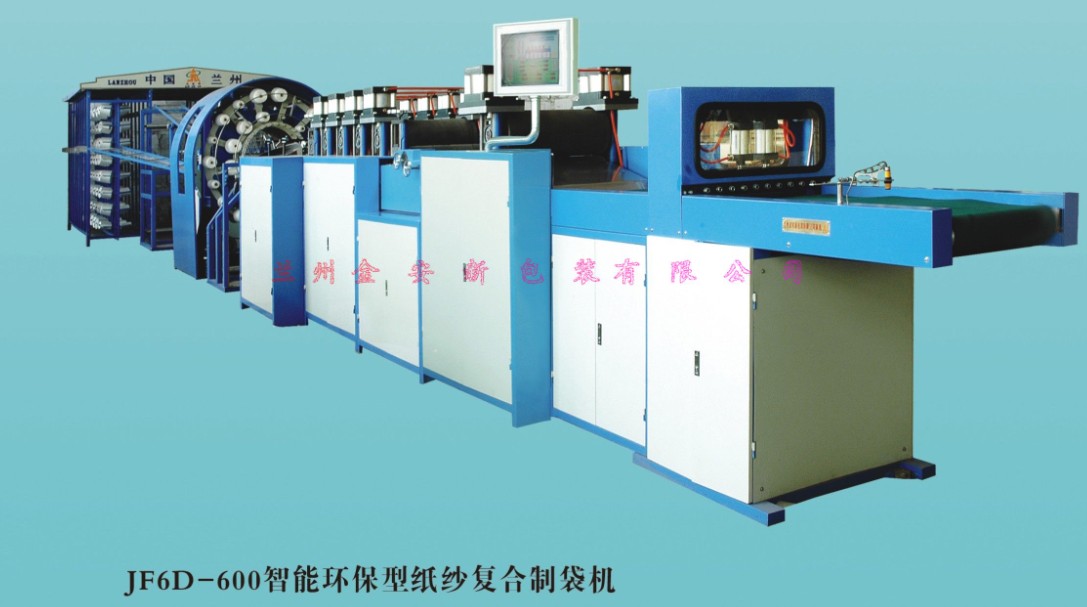

JF6D-600智能**型纸纱复合制袋机详细说明

JF6D-600智能**型纸纱复合制袋机设备性能: Jf系列型复合制袋机 Jf系列型复合制袋机所运用的制袋技术和工艺流程设计系国内**。该机投资省、见效快,是各类规模制袋企业的理想选择,其***特点和优越性如下: 二化:本机从设计上简化了一般制袋设备所需的庞大成套机组,如拉丝机、绕丝机、圆织机、复膜机、印刷机等。一次成型,工艺**;整机机电一体,从纸、纱、胶上机到纸袋成型、复合、折边、印刷、扎微孔、切袋、下机计数等全部实现了自动化。 三好:设备性能好,制袋速度20m/min,双色印刷清晰美观,运转平稳可靠。且一机两用,既能生产折边袋,又可生产扁平袋,制袋质量好;环境保护好,废袋可全部回收利用,系绿色产品。 一小:设备结构紧凑合理,占地面积小,单台设备占地面积为34m2。对厂房无特殊要求,设备基础浅,也不要上料进纸的装吊天车。 二少:操作定员少,耗电少。定员每班3人,1小时制袋1000条,耗电不到9度。 二快:设备安装快和掌握操作技术快。在厂房、人员等条件具备的情况下,半个月完成安装任务,学会操作技术。 三低:噪音低、劳动强度低、工作环境清洁卫生;制袋成本低,单位成本每条1.00元左右。 多功能:即能生产纸沙复合袋,又能生产多层纸袋;既能生产扁平袋,又能生产M折边袋;既能生产糊底袋,又能生产缝底袋。 Equipment Properties Sack-making technology and process desigh of Tpye Jf25 Machine is the pioneering in China.This machine is possessed of saving investment and becoming effective quickly, therefore it is anideal selection for all kinds of sack-making enterprise.Its superiorties are as following: 1、This machine simplifies the current sack-making equipments, such as wire-drawing machine, winding silk machine, circle loom machine, laying film machine and printing machine. Adopting the advanced process, the sack can be made by one machine. It can automatically finish the entire processes of material-feeding, sack-forming, compounding, printing, hole-pricking, folding and cutting. 2、Our equipment has excellent property, quality and environmental protection. Sack-making speed: It could reach 20ps/min, double color printing clearly and fine, running smoothly and reliable. The machine not only can produce margin-folding sack, also flat-plate sack. As green products the used sacks can be recycled. 3、 It is less space, compact and reasonable structure, occupied 34m2 only, no special equipments for workshop, no deep foundation, no hoist for taking paper. 4、 Fewer operators, Lower power consumption. Operator: 3 persons per shift. Output: 1000 pieces per hour Power Consumption: max 9 kv/h. Installing and training are easily, in the case of having enough working sites and operators, these tasks can be accomplished within half a month. 5、 Lower noise and labor strength and less cost, clean environment, unit cost of cement sack: RMB 1.00 Yuan more or less. 6、 With the function of making paper yarn or multi-wall paper bags, as well as margin folding sack, pasted sack and sewn open mouth sack. 主要技术参数: 1p原材料:维纶水溶纱(或牵切纱,涤维纱) **纸袋(或半伸性纸):80g/m2 粘合剂:17~99PVA 2p制袋规格(mm): 袋 长:任意长袋宽(扁平宽):420~600(标准配置480~550) 折 边 宽:78或0 3p印 刷:双色(标准配置印刷袋长790mm) 4p制袋速度:比较大20m/min. 5p操作定员:3人/班 6p供电功率:10kv 7p外形尺寸(m):16.65×2.9×2.2(长×宽×高) 8p整机重量:7000kg 注:制袋宽度p印刷袋长只提供标准配置,如有特殊要求,可另行定制. Major Technical Parameter: ● 1、Raw material:Vinylon soluble yarn(or polyester fiber yarn) National Standard Sack Paper:80g/m2 Binder:17—99PVA ● 2 、Specifications(Unit:mm): Length: optional length Width:Empty status:420~600(Standard:480~550) Folding width:78/0 ● 3、Printing: double color (Standard:790mm) ● 4、Speed:(Max)20m/min ● 5、Operator:3 workers/shift ● 6、Power:10Kv ● 7、Dimensions: 16.65×2.9×2.2(m) ● 8、Weight:7000kg Note: A set of standard width and length of sack making and printing supplied With equipment,also customized